When mats are unavailable at critical project phases, crews are forced to delay lifts or reconfigure ground support with alternate materials. Each hour lost increases project duration, adds labor costs, and impacts downstream scheduling for subcontractors and equipment.

LIFT PLANS & GROUND SUPPORT

Every successful lift begins with a solid foundation. A well-developed lift plan doesn’t just protect equipment—it protects crews, schedules, and budgets. Let's break down the essentials of lift planning, the importance of engineered ground support, and the role of TerraLam 700 Series mats in creating a safer, more reliable lifting environment amid a growing shortage.

LIFT PLANS

WHY LIFT PLANS MATTER

A lift plan defines how a load is handled by a crane or other lifting device in accordance with ASME P30.1 – Planning for Load Handling Activities. It provides a roadmap for performing lifts safely and within engineered limits, outlining equipment configuration, load data, rigging requirements, ground conditions, bearing capacity, pad or mat design, and required safety procedures. Engineered mat systems make lift plans more defensible by providing predictable load transfer characteristics. When ground bearing pressures can be modeled with engineered support, teams gain confidence in execution and reduce risk of surface damage or downstream disputes. Two factors largely determine success in the field:

Ground Support Is the Critical Variable

Even the most accurate load charts fail if the surface beneath the equipment deforms. Soil strength, mat stiffness, and load transfer between layers and the subgrade determine overall stability. Clay, sand, seasonal moisture, or groundwater can alter bearing capacity. Because inconsistent mat behavior can cause settlement or tilt that invalidates rated capacities, modern lift plans specify engineered mat systems with verified structural properties to ensure predictable performance.

Plan Early for Safety and Availability

Integrating mat selection early in the pre-construction phase turns ground support from a field adjustment into a controlled parameter. Early planning enables accurate ground bearing pressure modeling, secures mat supply, and minimizes downtime from stacking or scheduling delays. Evaluating alternates such as TerraLam® 700-series CLT alongside 12-inch timber keeps critical lifts on schedule even during material shortages, ensuring safety, consistency, and cost control.

HOW SHORTAGES CAN IMPACT LIFT PLANNING

12″ timber mats, aka crane mats, continue to be in short supply—driven by supply chain disruptions and increasing demand. Regional mills have struggled to keep pace, leading to inconsistent availability, poor quality, and unpredictable lead times. These shortages affect project schedules, costs, and safety margins, particularly when lift plans rely on specific ground support materials. Addressing the issue early in project planning is essential to maintaining workflow and compliance with engineered load-handling requirements. Common challenges include:

Schedule Delays

Increased Costs

Limited supply, inflation, and other factors drive higher prices for timber mats and freight, particularly when materials must be sourced from distant mills. Emergency procurement and expedited shipping to meet lift schedules can erode profit margins and strain project budgets.

Equipment Idle Time

Cranes, haul trucks, and other heavy machinery represent significant daily costs when standing idle. Without adequate ground support, equipment cannot be deployed safely or efficiently, resulting in lost utilization hours and lower overall project productivity.

Planning Inefficiencies

Waiting until mats are needed forces engineers to redesign ground support on the fly, often without current soil or bearing data. Early integration of mat selection in lift planning allows teams to model actual ground bearing pressure (GBP), secure material supply, and evaluate engineered alternatives.

WHY CONSIDER TERRALAM 700s?

The TerraLam® 700 Series provides an engineered solution for crane pads and travelways, offering the strength and stability required for heavy lift operations. For large-scale projects sourcing mats from multiple regions, TerraLam 700s eliminate freight disparities and supports scalable production. With sufficient lead time, Sterling can manufacture large quantities as needed, making project estimates more predictable.

Defensible Load Verification

TerraLam 700 mats support more confident lift planning by reducing uncertainty in ground support assumptions. With predictable performance under load, teams can better evaluate whether surface issues stem from soil conditions, equipment loads, or access methods, helping protect schedules, budgets, and accountability on complex sites.

Highly Engineered

TerraLam mats are a highly engineered product system with known bending, shear, and compression values. This provides known load-response characteristics that support ground pressure calculations. Unlike other traditional hardwood mats, which can vary by species and assembly, TerraLam 700 series mats offer controlled, repeatable material properties that help engineers evaluate bearing capacity.

Reliable Supply Options

The limited availability of 12″ timber crane mats continues to delay projects as smaller mills struggle to meet demand. For large-scale jobs requiring high volume of mats, the TerraLam® 700 offers a logistical advantage over hardwood timbers: consistent production, scalable volume, and substantial freight savings.

Easier Handling

Timber crane mats are heavy and requires more effort to move. TerraLam® 700 mats weigh approximately 50% less than timber mats, allowing more coverage per truckload and reducing lift and placement cycles in the field. The lower weight supports faster setup and relocation without changing required bearing performance.

Want to learn more about how TerraLam 700 mats compare to 12″ timber crane mats?

Superior Load Dispersion

The unique cross laminated design of the TerraLam mat means it distributes loads across the entire mat in all directions while timber mats only transmit loads well across one direction. TerraLam’s larger footprint, up to 100% more surface area, also means a improved load dispersion and substantially less pressure transferred into the ground.

Consistent Performance

TerraLam® mats are an engineered product produced on a precise automated assembly line. Their physical qualities are consistent mat to mat with dimensions and weights all within tolerance. More importantly, engineering values are highly consistent, increasing confidence that the crane will be supported and the ground protected during lift cycles.

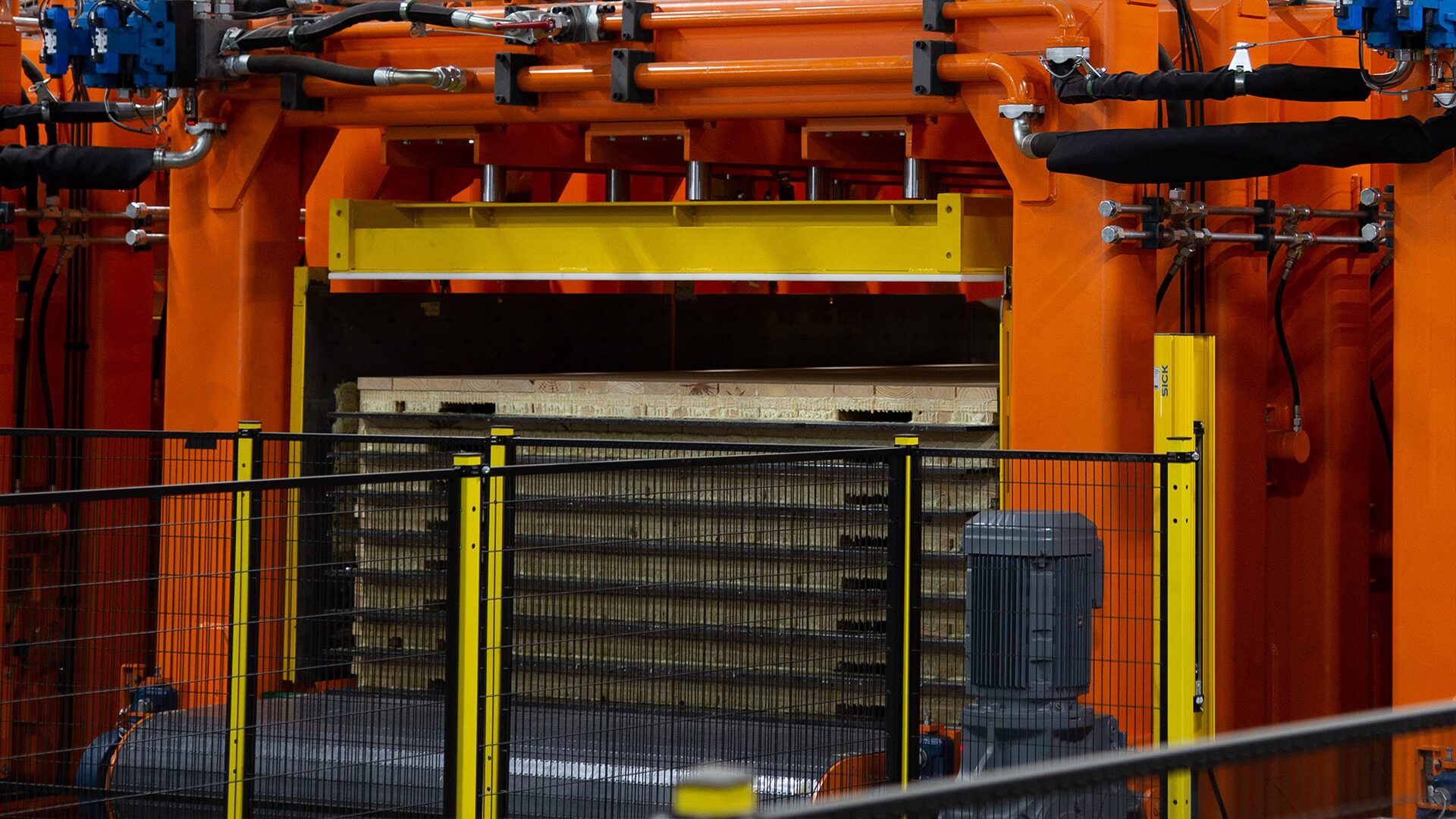

Precision Manufacturing

TerraLam® mats are built under a controlled process to ensure consistent strength and accuracy. Automated presses track temperature, pressure, and cure time to confirm full bonding, while finished mats are checked for thickness, flatness, and alignment. Internal testing verifies that known values remain within published limits and aligned with ASME P30.1 planning standards.

Want to learn more about how TerraLam mats?

DISCOVER THE TERRALAM DIFFERENCE

Stronger, lighter, and more durable than traditional mats, TerraLam offers a smarter ground protection solution for your job site. Don’t settle for outdated materials when you can improve safety, efficiency, and cost savings.