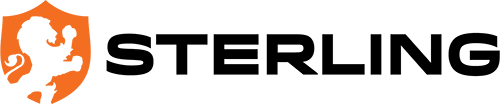

TerraLam offer superior load distribution due to cross-laminated construction and increased surface area. With up to 100% more coverage than a 12″ crane mat of the same length, TerraLam can reduce transmitted ground pressure, creating a more stable surface for heavy equipment and better protecting the ground.

ADD TERRLAM TO YOUR CRANE SITE

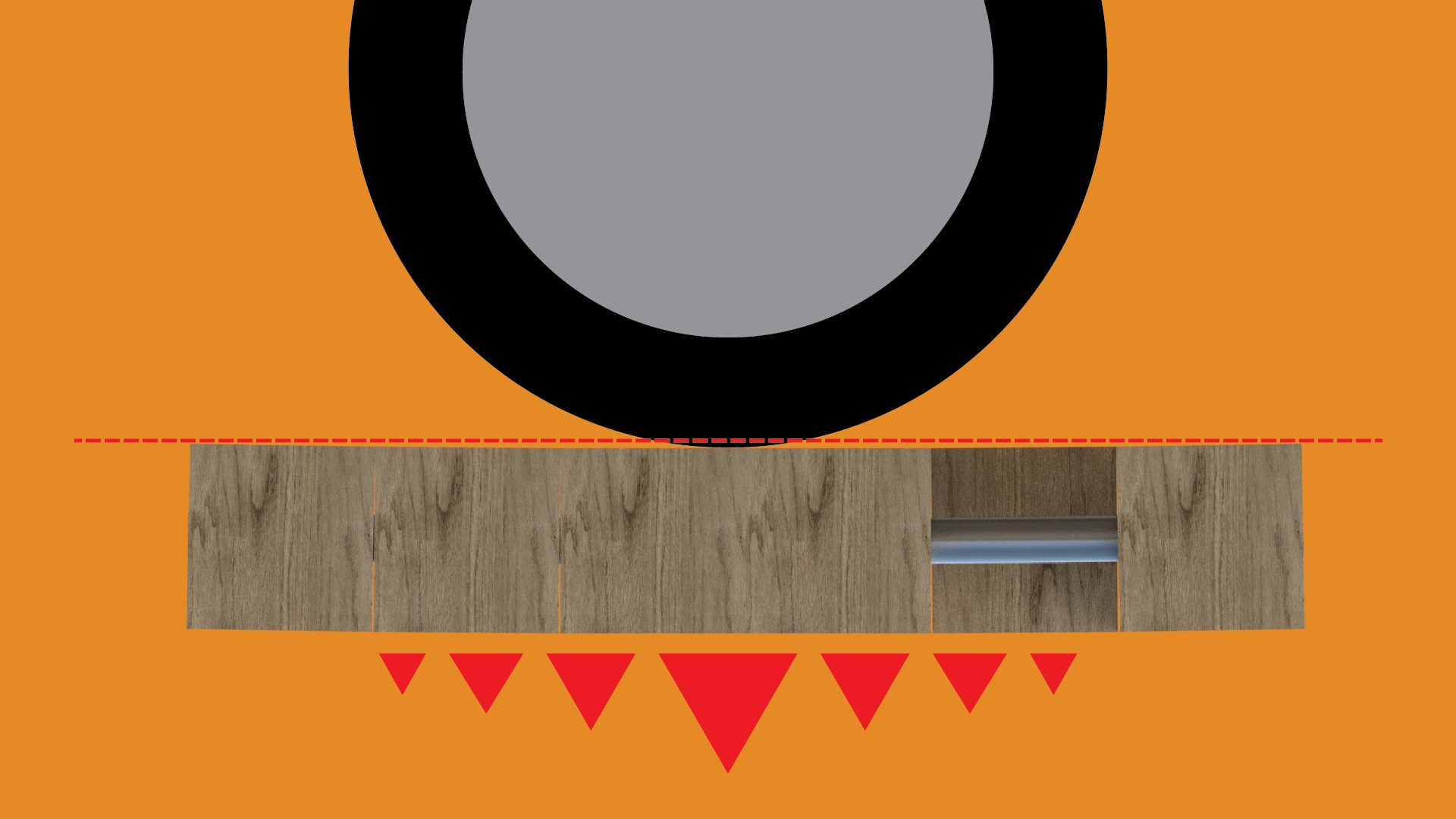

The 12" timber mat (aka crane mat) has been a reliable option for heavy-duty support. But when your project calls for greater safety and efficiency, TerraLam 708 offers a smart alternative for many lift scenarios. With an engineered, lighter, multi-layer design, they simplify transport and installation while maintaining strong load-bearing capacity—helping you save time and potentially lower costs.

TERRALAM VS CRANE

Known Engineering Values

TerraLam is an engineered product consistently made from high quality, graded Southern Pine in a controlled process, which allows it to carry verified engineering values. This advantage allows TerraLam to be used in situations where specific load ratings or ground pressures are required, unlike with mixed-hardwood timbers.

Smarter Layout, Fewer Mats

In lift situations where sidewalking is appropriate, TerraLam’s 8ft width allows it to be placed parallel to tracks while maintaining proper overhang ratio for many track sizes. This allows one TerraLam to replace up to four (4) 4ft crane mats, reducing mat count, installation time, and project cost without compromising load distribution.

Readily Available

TerraLam mats are made in Illinois and Texas using domestically harvested Southern Pine. These centrally located factories can each produce 1000 mats per day for even the largest projects. And because they are lightweight, transport costs are substantially lower than with other types of mats such as timbers.

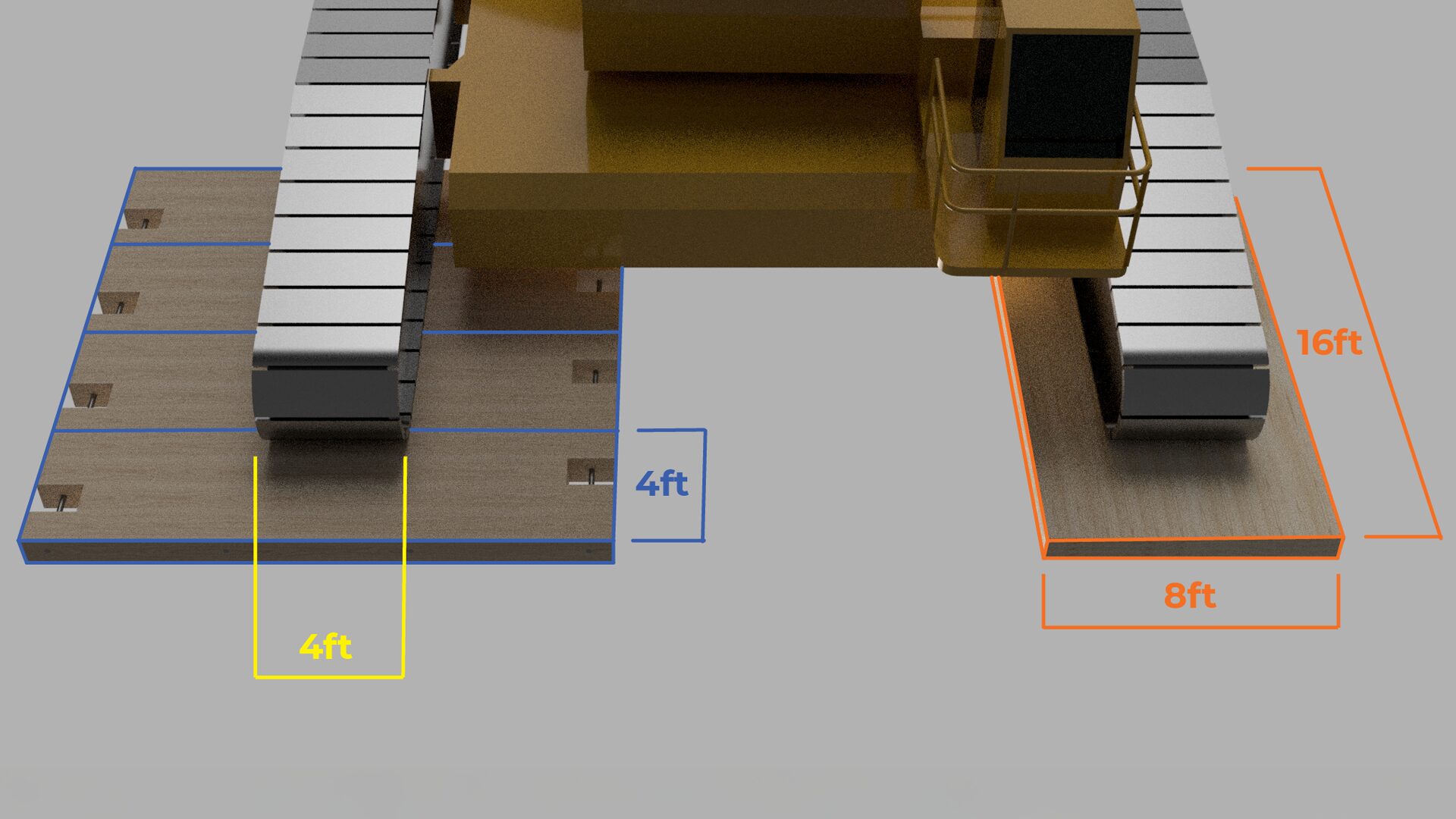

Reduced Point Load Hotspots

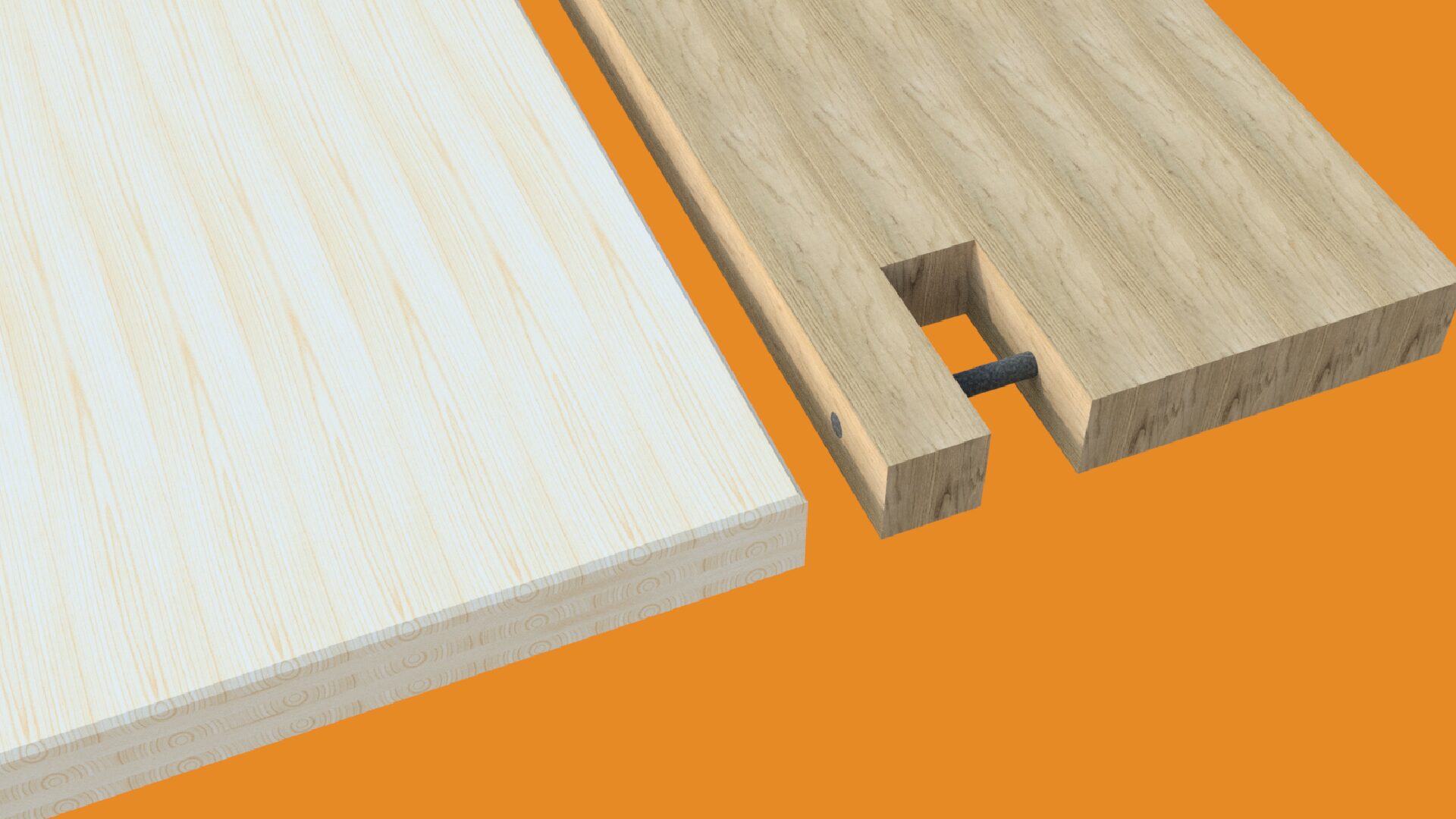

Timber mats are wood beams held together by steel rods, which can flex under load in certain situations. When these mats flex in the center, surface forces transfer into the ground below. TerraLam’s cross-laminated construction reduces hot spot chances by distributing load more evenly across the mat.

Faster to Install

Delivering twice the coverage per mat in more consistent dimensions means less trips down the Right of Way when installing TerraLam 700 mats compared to crane mats. Less fuel spent plus faster setup while site safety also improves. These same benefits apply during removal too.

Safer for People

Timber mats (right) usually include a large lifting notch on each side. This gap introduces a severe trip hazard to the jobsite and is recommended to be covered with plywood or filled in with gravel, requiring additional labor and cleanup. TerraLam’s (left) nearly gap-free surface avoids this hassle and provides a safer surface to walk on.

Safer for Concrete

TerraLam mats provide a wood-based alternative to steel plates when moving heavy equipment across concrete surfaces. Wood’s softer composition reduce the risk of damaging expensive surfaces through corner contact or drops, making TerraLam mats better suited for warehouses, slabs, and other finished or sensitive areas.

Superior Surface Protection

TerraLam’s Southern Pine CLT construction gives it the ability to absorb and disperse shock better than rigid materials like hardwoods or steel. When impact occurs, forces are spread throughout the mat, reducing the penetrating forces going through the mat, and lowering the risk of point load shock that can cause structural or surface damage.

Lower Freight Costs

All TerraLam mats are lighter (up to 50% less) compared to traditional wood mats, including crane mats. With up to twice the lineal footage per truckload, shipping expenses and transport time are dramatically reduced. Using TerraLams in areas like your Right of Way can increase efficiency over time compared to using crane mats alone.

Consistent Product

Each TerraLam is manufactured from dimensional lumber with precise specifications, ensuring uniform thickness, smooth surfaces, and reliable structural integrity. This consistency, that timber mats just can’t match, improves installation efficiency but also enhances safety and durability on-site.

Easier to Clean

All TerraLam mats feature a smooth, nearly gap-free surface that simplifies cleaning and maintenance. Dirt and debris can be quickly brushed off the surface and a lack of gaps means minimal buildup within the mat, reducing the weight gain from the jobsite dirt and the chance of invasives tagging along.

Are you ready to elevate your job site performance? While timber mats are incredibly strong and reliable, consider the advantages of the TerraLam mats. Don’t let traditional solutions hold you back—add TerraLam to your timber sites today and experience the difference! Contact us at 708.388.2223.